DIW (also called Robocasting) is an additive manufacturing technology that is commonly used for the manufacture of ceramic or metal parts (which later go through an oven to consolidate), or any bioprinted material.

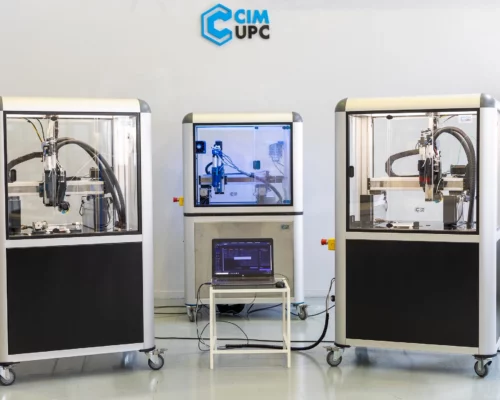

Based on many specific realizations of 3D printers on request, the CIM UPC has developed a concept of a 3D printing platform that has come to be called PowerDIW. Specifically, the users (RDI departments of companies and research groups) come from the fields of metallurgy, fuel cells, composites, advanced ceramics and tissue engineering, as well as for a wide range of research fields, in which additive manufacturing is a new disruptive actor, and which is also capable of making a great extrusion power, without equivalent solutions on the market, either for performance or for its focus on research activities of the equipment to materialize.

The PowerDIW platform is fully configurable for the needs of each user. Ask us about it, the achievements made are very varied and we will find the way for additive manufacturing through DIW to revolutionize your processes and products.

Usually two DIW print heads are included with a genuine lifting mechanism. While the first print head works, the second one rises, thus avoiding dragging the wrong material for printing. The two print heads offer high pressure that can reach forces of up to 850N, which typical syringe-based DIY systems cannot deliver. The material is processed in standard syringes, enclosed in an armored casing, easy to clean and configure thanks to a quick change system. Many other benefits are customizable and adapt to the requirements that are formulated.

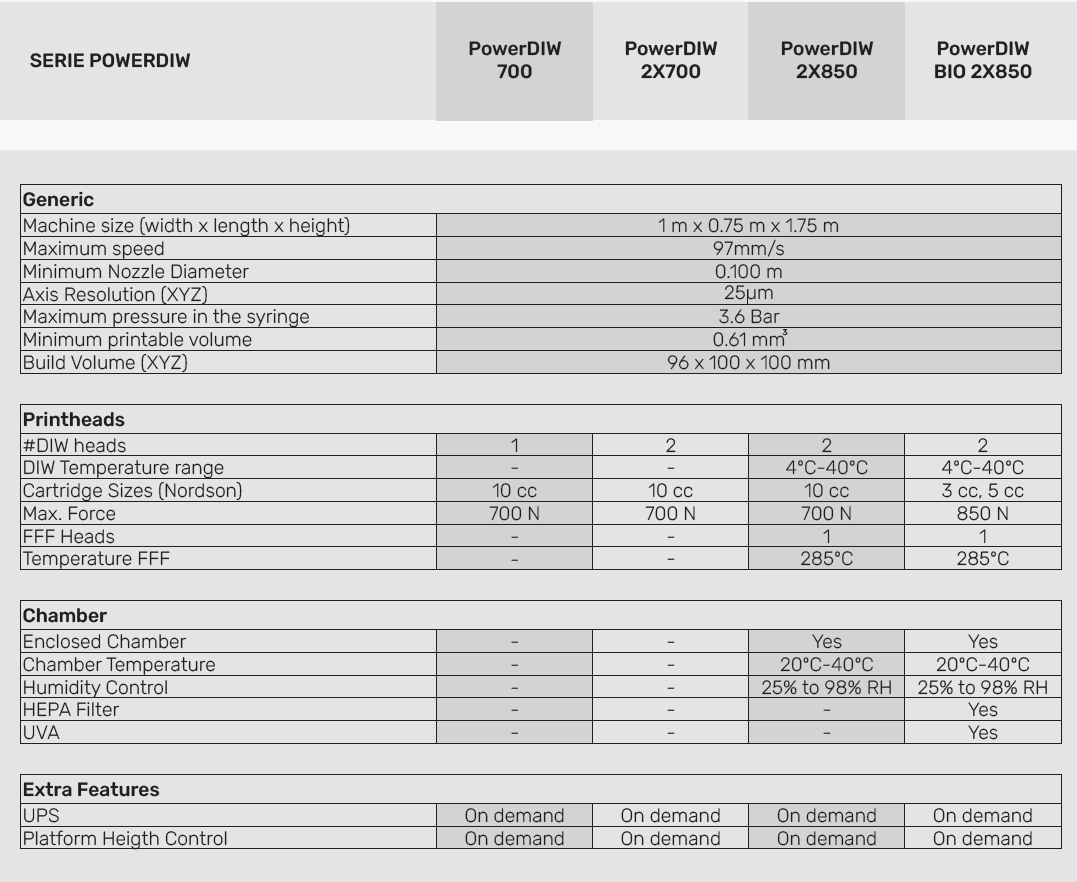

Characteristics:

- Full control of printing parameters (temperature, pressure, speed, etc.) through software and movement.

Multiextrusion system up to 2 DIW and 1 FFF head. - A wide range of materials can be used: ceramic, metal, metal oxides.

- High pressure system up to 850N.

- High quality mechanics and movement.