The main objective we have in the Concrete 3D Printing group is to develop new techniques and processes for large-scale 3D printing of ceramic materials for the construction of buildings or prefabricated houses, achieving a significant impact in the environmental, social and economic spheres and becoming a global benchmark in the new concept of Construction 4.0.

The construction world has been using 3D printing for many years to obtain models of architectural projects, but the technology we are developing in the Concrete 3D Printing line goes much further. The goal is for 3D printing to allow architects and engineers much more freedom to design structures with new geometries that would be impossible to build with a traditional process.

The main advantages offered by the incorporation of 3D printing in the construction sector are:

The GOLIATH project proposes to create and demonstrate a practical methodology for the use of additive manufacturing in the construction sector with a clear objective, to reduce the amount of material used in structural precast in order to reduce the environmental impact derived from excessive use. of cement in modern society.

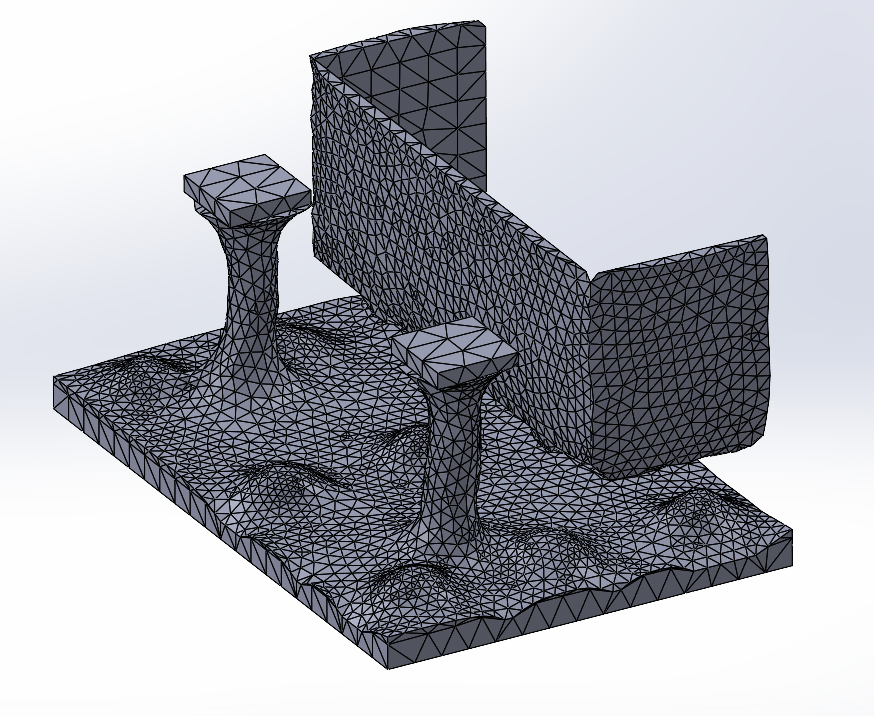

But how to reduce the use of cement? GOLIATH during the development of the project, the same methods that have been applied in other sectors such as aeronautics with the 4.0 revolution will be applied: allowing additive manufacturing together with topological optimization to reach its full potential.

Topology optimization calculations result in geometries that allow material volume reduction, but are often complex to manufacture with traditional manufacturing technologies. It is at this moment where Additive Manufacturing becomes especially important, allowing the materialization of advanced geometries.

Participants: Lagula Arquitectes; Polytechnic University of Catalonia (UPC); CIM

Project reference

PLEC2022-009441

Program and call

“The publication/result/equipment/video/activity/contract/other is part of the project PLEC2022-009441, financed by MCIN/AEI/10.13039/501100011033 and by the European Union “NextGenerationEU”/PRTR.”

Project financed by the MINISTRY OF SCIENCE AND INNOVATION within the framework of public aid for public-private collaboration projects, of the State Program to Promote Scientific-Technical Research and its Transfer, of the State Plan for Scientific, Technical and Innovation Research 2021 -2023, within the framework of the Recovery, Transformation and Resilience Plan, and by which the call for early processing corresponding to the year 2021 of these aids is approved.

PRINT & BUILD aims to design a prototype machine capable of materializing a building using large-scale additive manufacturing technology.

The PRINT&BUILD project is based on introducing Rapid Prototyping (additive manufacturing) technology techniques, in the construction sector, to obtain 3D homes. However, the application of 3D technologies in the field of construction has been studied, but to date, it has not been achieved due to the difficulty of:

- Develop valid materials for 3D printing.

- Apply 3D printing technology on a large scale.

The challenges posed by the present project are based on overcoming the previously mentioned difficulties, developing new techniques and materials that can replace the concrete currently used in construction. Applying the new technology on a large scale represents a new scenario with respect to what has currently been developed in 3D printing, which is based on designs of plastic parts and their subsequent printing on a laboratory scale.

3DCONS is based on the introduction of 3D printing technologies to the construction industry, new construction, rehabilitation and heritage restoration. It is focused on the development of new construction processes and materials that integrate 3D printing systems.

The 3DCONS project faces major technological challenges for the construction sector such as: New typologies of “printable” materials and with specific requirements in application and benefits; Development of new technologies for direct printing on vertical elements such as existing facades and the printing of prefabricated “a la carte”; New design paradigms in new construction and rehabilitation.

This project has been co-financed with FEDER funds through the CIEN Strategic program of the CDTI.

The HINDCON project aims to adapt manufacturing technologies to the construction sector, move towards industrialization and overcome the limitations of approach to introduce additive and subtractive manufacturing in construction activities.

The project aims to solve some important problems in the sector such as the lack of flexibility in manufacturing processes, the low productivity rate or the high manufacturing times of unique products, which cause a negative impact on the costs of customized products.

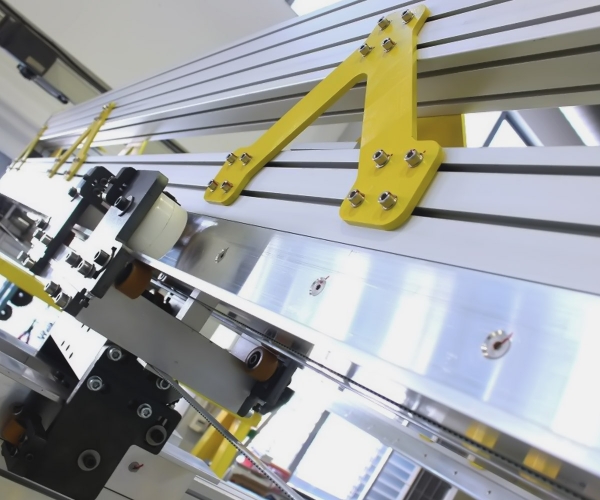

To achieve this, the collaborating entities have developed and demonstrated a hybrid machine of additive and subtractive technologies with mortar, bringing to the sector an innovative technology that reduces environmental impact and at the same time reduces economic costs in high value products added

Project financed by the European Commission, within the framework of the Horizon 2020 program. Grant Agreement No. 723611

The overall goal of the project is to develop a new 3D printing system (3DPS) that fuses an innovative print head and a new cement-based material with sensorized structural orientation.

The new 3DPS will be designed to cover a wide range of building components and street furniture. This 3DPS will guarantee an increase in productivity compared to existing conventional prefab techniques and a significant improvement in parameters related to sustainability. Embedded sensors will have the ability to transfer information on environmental variables (temperature and humidity) and degradation status (fatigue or durability issues) so that active energy efficiency and repair measures can be proactively programmed and applied.

Project reference

PLEC2021-007982

Program and call

“The publication/result/equipment/video/activity/contract/other is part of the project PLEC2021-007982, financed by MCIN/AEI/10.13039/501100011033 and by the European Union “NextGenerationEU”/PRTR.”